Ideal for pipeline construction using gravitational drilling technology

We recommend pipe modules to make pipelines using the Gravity Drilling Technology, especially in places with limited installation space wells. Pipe modules are made of polypropylene (PP).

Polypropylene (PP) is used for their production. The production uses the method of extrusion. Polypropylene (PP) is a material with high resistance to chemicals. Pipes made of PP are resistant to pH 2 to pH 12, corrosion caused by water such as municipal sewage, rainwater, surface water and groundwater. Pipes made of polypropylene have a very high smoothness of walls, as a result of which we obtain very low flow resistance. Polypropylene is characterized by a lack of moisture absorption and a very high chemical resistance. These characteristics make the pipes made of polypropylene have very low ability to fouling of the internal surfaces of the sewer pipes. Pipes made of PP work thermally, i.e. they change their dimensions depending on the temperature. This additionally promotes the removal of sediments which, as a result of changes in the dimensions of the pipes, break and are washed away by the flowing stream of liquid flowing in the pipeline. Another important feature of pipes made of PP plastics is their flexibility. Compared to the rigid, traditional vitrified clay pipes, pipes made of PP are more resistant to mechanical damage, leakage of the installation, occurring as a result of stresses resulting from soil movement.

The most important features of underground installations made of PP pipes:

- high corrosion resistance

- high chemical resistance

- high abrasion resistance

- low roughness

- high mechanical strength

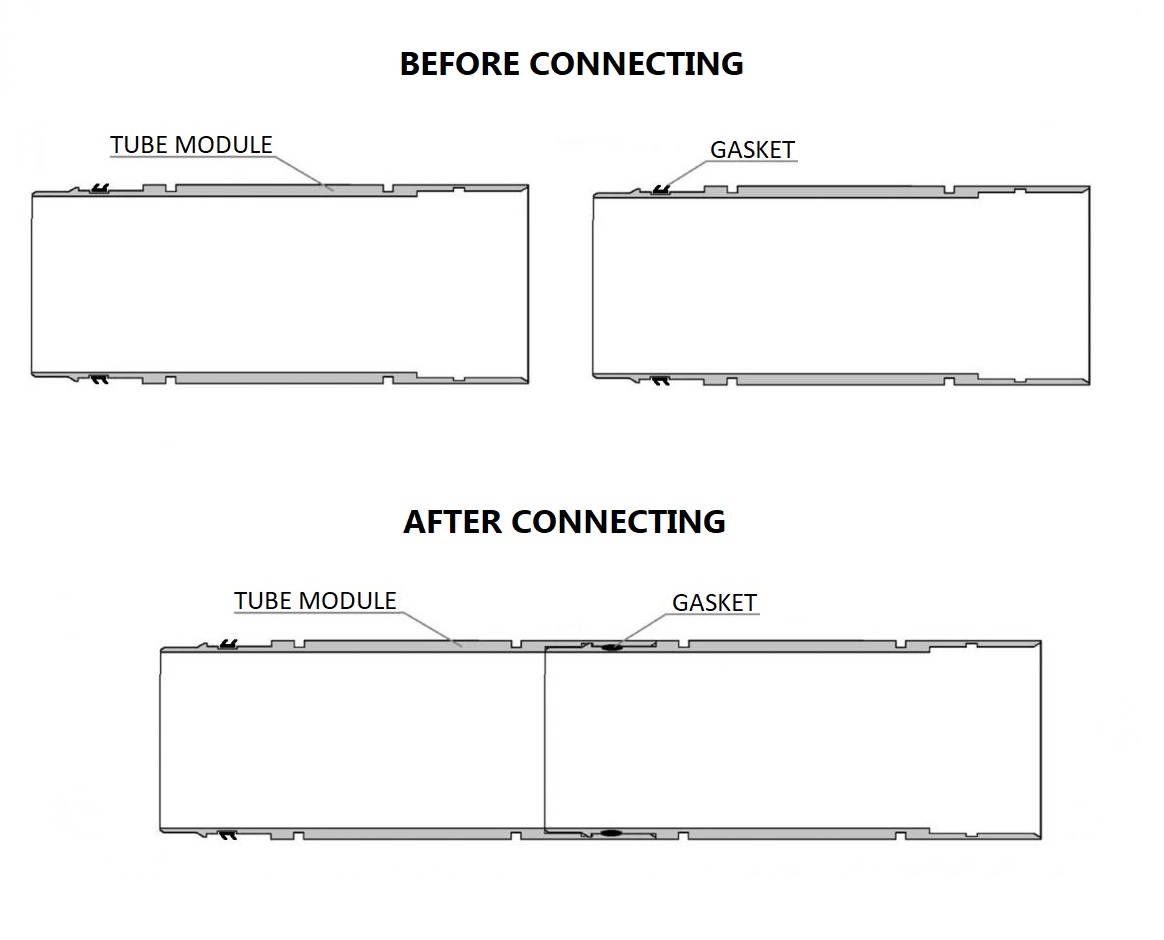

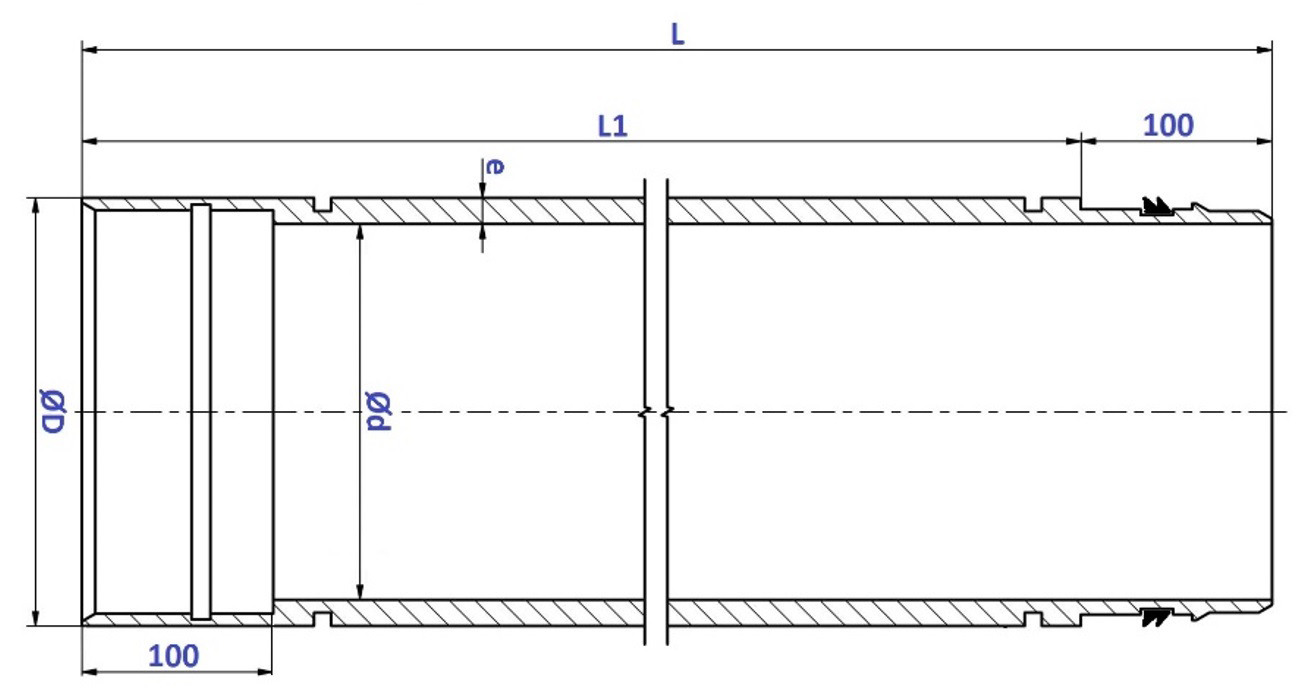

By machining the pipes, locks are made, i.e. elements responsible for connecting subsequent segments to each other. The tightness of the connection is achieved by a NBR rubber gasket.

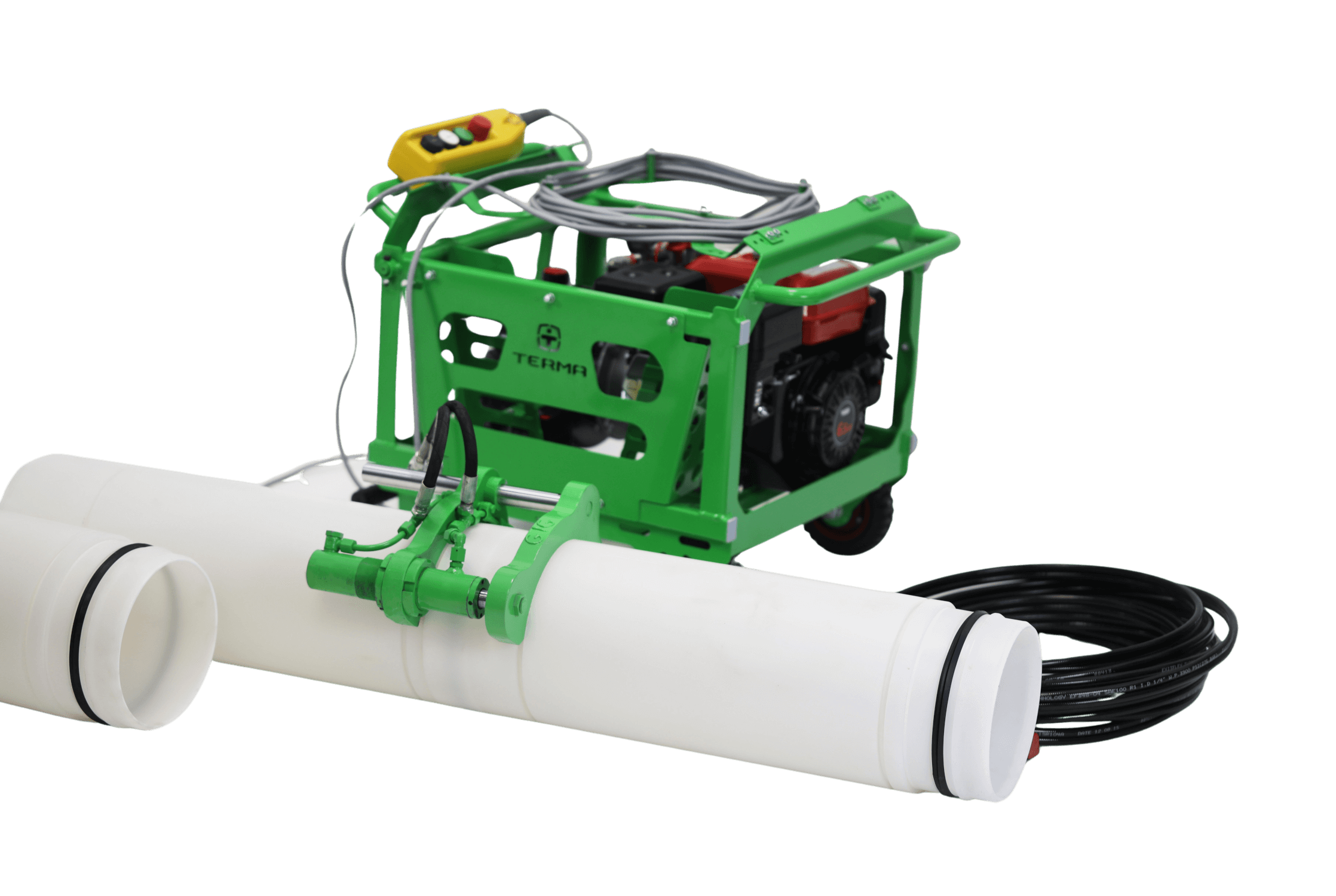

The PP pipes we use are made of the highest quality materials. We guarantee the reliability of the installations arranged from them. All machining activities are performed on precise CNC machining centers. Modular pipes are connected with a compact hydraulic joining tool, adapted to each pipe diameter.

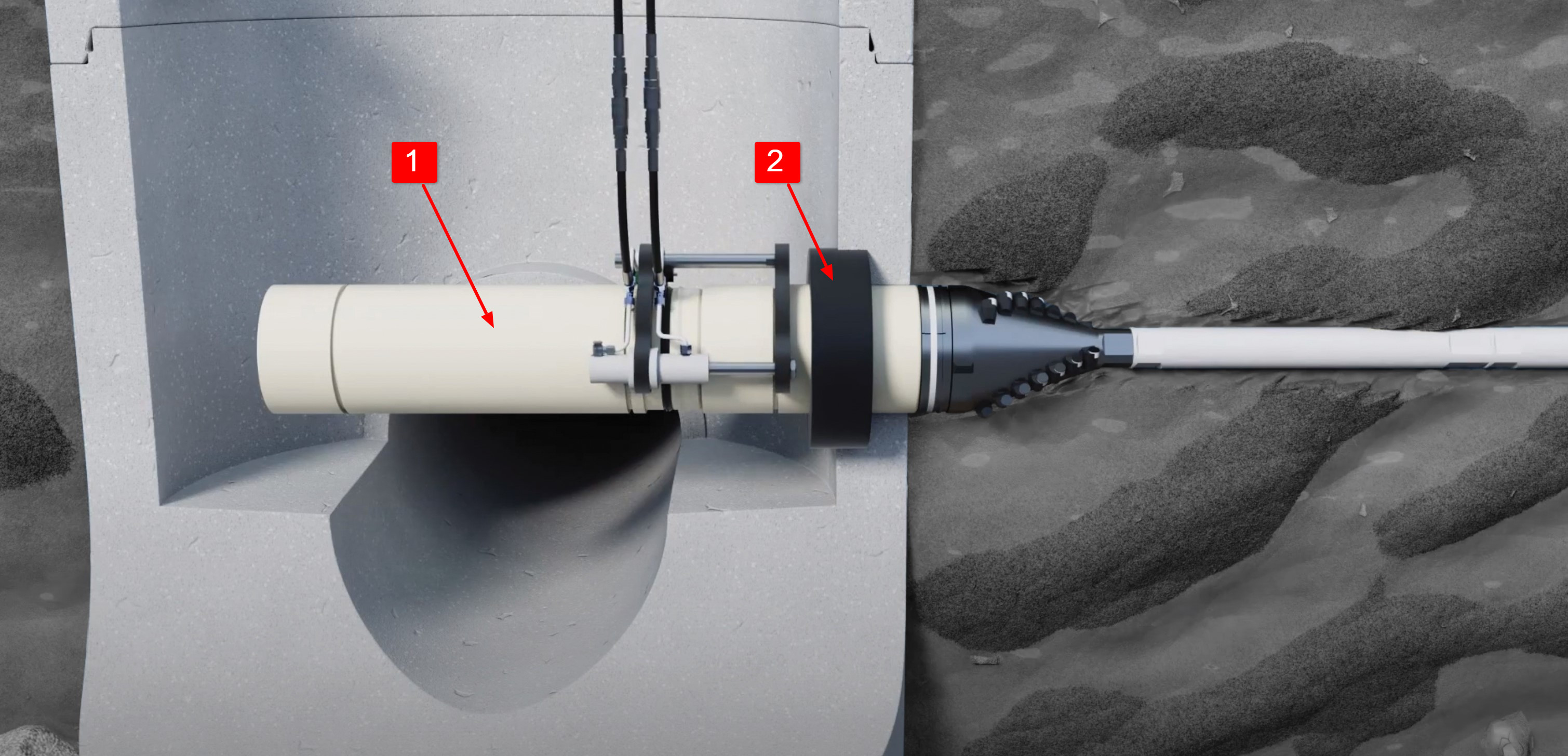

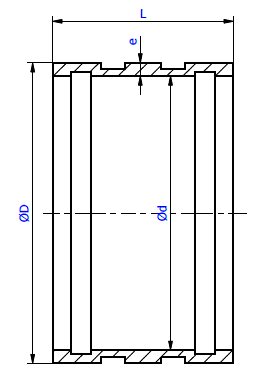

The total length of modular pipes with the introducing and expanding pins is 700 mm. Longer modular pipes with a length of no more than 1000 mm can be produced. Modular pipes are intended for the construction of non-pressure networks outside and under building structures (application area code "UD"). The pipes are used for the construction and renovation of a non-pressure network using the traditional method (in an open trench) or the trenchless drilling method (gravity drilling).

The pipes are especially used in places with limited working space, such as in the DN 1200 manhole. A sewer pipe is built in the well by connecting successive pipe segments to each other.

The range of manufactured diameters of Modular Pipes:

| Parameter | Unit | Ø110 x 10 | Ø180 x 13 | Ø225x13.8 | Ø250 x 14,2 | Ø280 x 15.9 | Ø315 x 17.9 | Ø400 x 22,7 | Ø450 x 25 | Ø500 x 28,3 |

|---|---|---|---|---|---|---|---|---|---|---|

| Ø outside (D) | [mm] | 110 | 180 | 225 | 250 | 280 | 315 | 400 | 450 | 500 |

| Ø inside (d) | [mm] | 90 | 154 | 197,4 | 197,4 | 248,2 | 279,2 | 354,6 | 400 | 443,4 |

Wall thickness (e) | [mm] | 10 | 13 | 13,8 | 14,2 | 15,9 | 17,9 | 22,7 | 25 | 28,3 |

Max. tensile force | [kN] | 22 | 40 | 65 | 69 | 82 | 105 | 125 | 140 | 155 |

Max. Pressing force | [kN] | 45 | 70 | 110 | 120 | 140 | 200 | 210 | 220 | 230 |

Net length(L1) | [mm] | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 |

Gross length (L) | [mm] | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 |

| Module weight | [kg] | 1,65 | 3,6 | 4,47 | 6,79 | 6,95 | 8,81 | 14,26 | 18 | 22,28 |

TRANSITION BUSHINGS

Sealed transitions in manholes are an essential element of a properly functioning sewage system. They allow for a tight connection between the sewer pipe and the manhole. The passage of channels through the walls of the manhole must ensure tightness to prevent, on one hand, the infiltration of groundwater along with soil (infiltration), and on the other hand, the leakage of sewage (exfiltration). For this reason, so-called transition sleeves are used to seal the connections between the pipe module and the concrete manhole. These are made from thick-walled polyethylene PE HD100 pipes. The diameter of the sleeve is adjusted to the diameter of the pipe module used for drilling. This solution is dedicated to gravity drilling technology.

Range of production diameters for transition sleeves:

| Parameter/for which module | jm | Ø180 x 13 | Ø225 x 13.8 | Ø280 x 15.9 |

|---|---|---|---|---|

| Ø outside (D) | [mm] | 200 | 250 | 315 |

| Ø inside (d) | [mm] | 183 | 228 | 284 |

Wall thickness (e) | [mm] | 8,5 | 11 | 15,5 |

Gross length (L) | [mm] | 150 | 150 | 150 |

Weight | [kg] | 0,52 | 0,90 | 2,18 |