Meet the technology

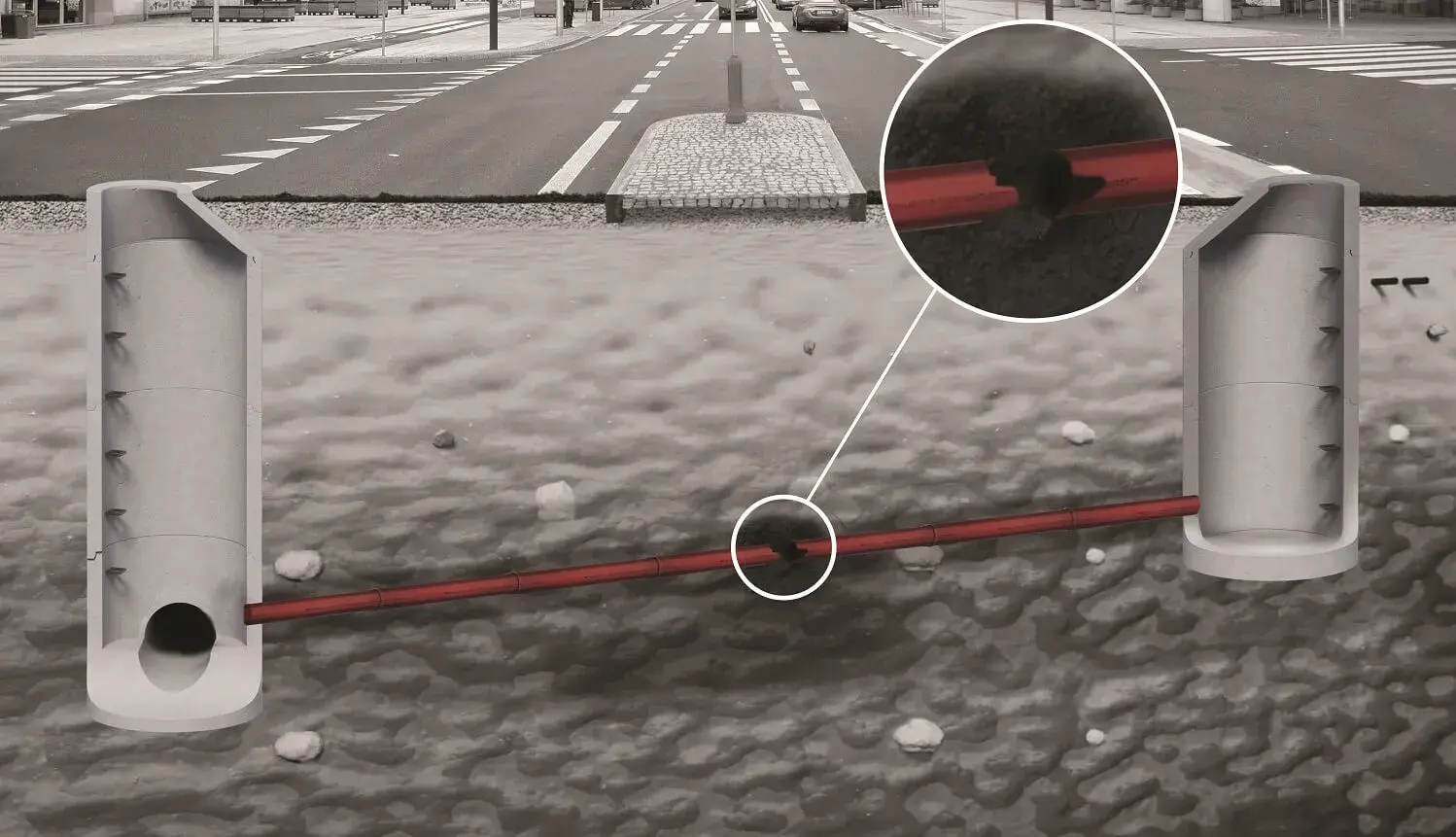

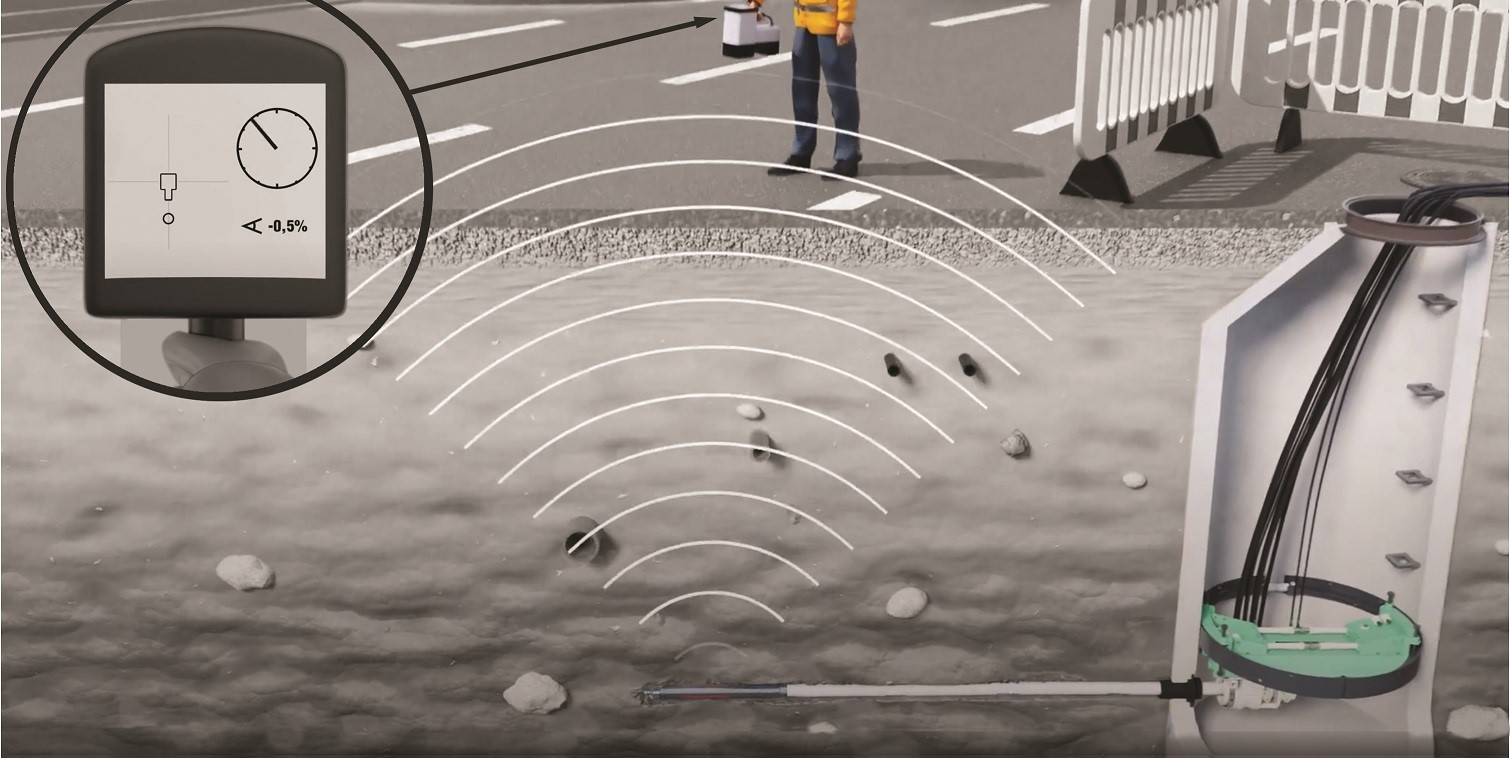

The technology of Gravity Drilling, using MTM 1200 Gravitational Drilling equipment, allows for fully trenchless and completely non-invasive implementation of water and sewage systems in the existing infrastructure. In particular, it is applicable when it is necessary to install a network between the existing sewerage chambers in dense urban development.

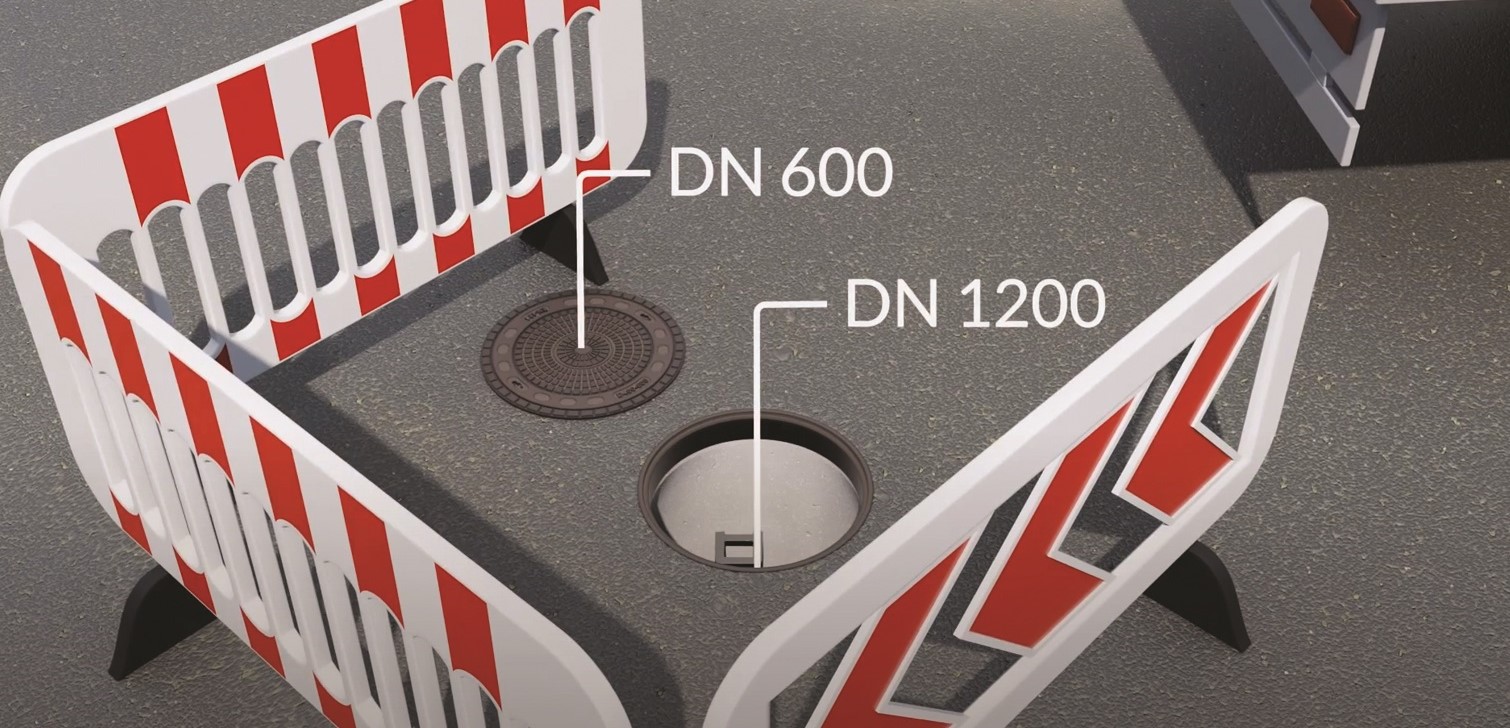

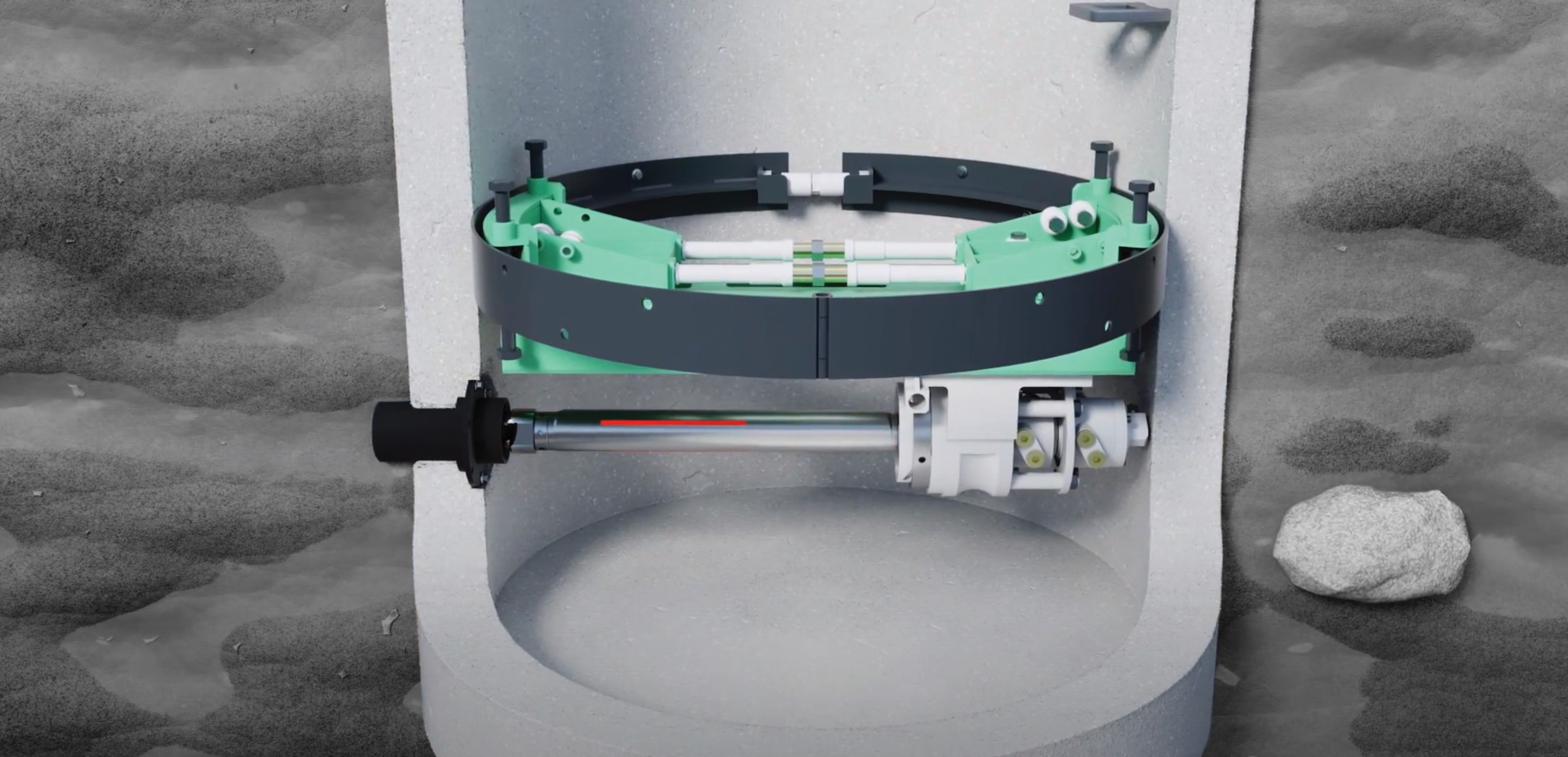

The small dimensions of the drilling device allows it to be inserted through a typical DN600 manhole and installed in typical DN1000 DN1200 and DN1500 wells.

You only need to designate and separate the traffic lanes from the well.

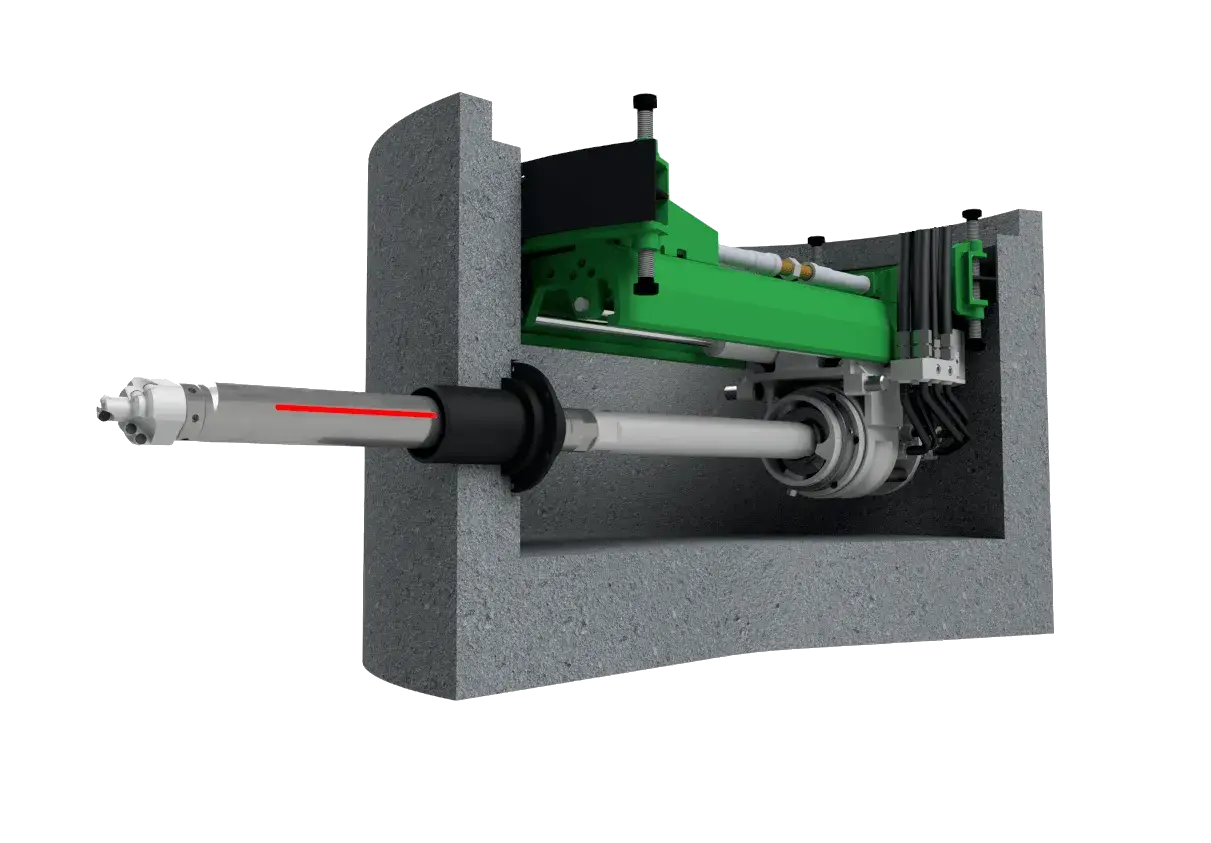

The implementation of work between non-standard dimensions and sizes of wells is also possible through the use of a portable starting chamber and adapters in which the drilling rig is installed.

Also it is possible to implement installation works in wells with low mechanical strength. The technology of gravity drilling allows the construction of sewage networks in different ground conditions and depth. The presence of groundwater is not an obstacle. The precise location system, together with the innovative drilling head control system, allows the connection to be made with the highest possible accuracy, reaching 0.2%.

Most often, the Gravitational Drilling Rig is used to make network between typical DN1200 wells, in densely built-up urban agglomerations.

FEATURES / ADVANTAGES OF THE GRAVITATIONAL DRILLING TECHNOLOGY

- the starting chamber is a well (new or existing) DN 1000, DN 1200 or larger.

- implementing installations from typical wells without interfering with the surrounding infrastructure.

- the drilling machine is placed in the well through a typical DN 600 manhole.

- the installation does not require any excavation, work begins and ends in the wells.

- no need for starting chambers and their drainage

- installing the machine in chambers of any non-standard shape

- working from the excavation with the use of a mobile starting chamber and / or adapters

- performing works from a starting well with low mechanical strength

- working in a well equipped with space limiting elements without the need to disassemble them

- making installations at any depth.

- the technology enables sewerage to be made with an accuracy of 2 ‰ gravitational slope

- the drilling rig can work at the very bottom of the well and directly under the well cover.

- drilling is possible below the groundwater level. This applies to the entire boring route, including the area around the well.

- work in soils with drilling classes: II, III, IV, V (sand, gravel, clay and soft rocks, medium: marly limestones, order clay, marls, sand shales, rubble, concrete obstacles).

- the technology does not reduce soil compaction, it allows for compacting the zone around the pipe to be installed.

- when drilling works on active collectors, it is not necessary to block the sewage

- the highest efficiency of the installation compared to other available trenchless technologies

Last projects realized using our technology