With the use of gravity drilling technology using the MTM 1200, the rainwater drainage connections were made with a diameter of 225 mm and 315 mm, each with a length of about 14 meters.

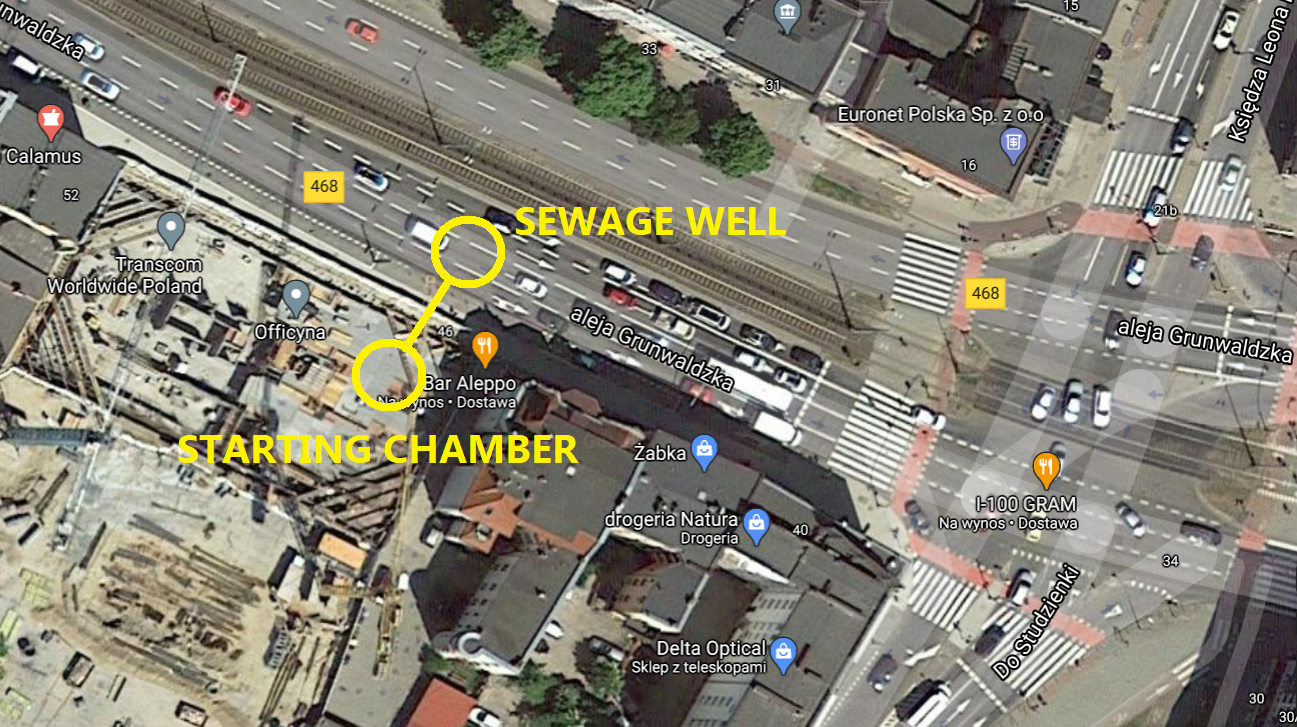

Sewer connections had to be made with a precisely set slope between the infrastructure of the building under construction and the existing retention system. The connection point was the existing DN1200 sewage well, located in the middle lane of a busy road.

Due to the strategically connected location, it was unacceptable to use any technology that would cause significant traffic disruption, which would certainly be the case with other technologies, including typical trenchless machines and technologies, such as auger drilling rigs or microtunnelling. The use of the Gravitational Drilling Rig resulted in only a few hours' shutdown of one of the three lanes of Al. Grunwaldzka.

The drilling process was carried out by pilot drilling, from the starting chamber with the Gravity Drilling Rig placed in it, to the well located on the street. Pilot drilling required high precision, which was a factor in achieving the desired gravity drop of the installation.

After obtaining a drilling head of a sewage well, it was equipped with a head enabling simultaneous drilling of a hole and installation of a sewage system.

The individual sections of the sewer pipe were built of pipe modules connected directly in the sewer well. The developed technology of joining and sealing pipe segments ensures effective, tight and durable connection, which guarantees the highest quality and durability of the network.

The used pipe modules have the Technical Approval of the Building Research Institute, valid in Poland. A similar document is available in other countries.

Then, by pulling the drilling head back from the well into the starting trench, an installation was made, consisting of successively connected pipe segments.

The main advantage of the technology with the use of the MTM 1200 Gravitational Drilling Rig System is high efficiency of implementation, especially in networks requiring very high precision and accuracy of gravity drop. Another advantage is that there is no need to interfere with the existing infrastructure. The technology enables to provide the work 100% trenchless. This results in lower traffic restrictions and other difficulties for the local society. Reducing the working time with the use of Gravity Drilling technology means significant savings for local budgets. It is also support in the fight for a clean environment, clean air and environmental friendliness in construction processes.